AUTOpack™:

a machine-handleable bag for automated packing

Potatoes,

carrots, grapes, radishes, and other agricultural products ...

as well as industrial products like washers, candies, pumbling

parts, repair

kits, bolts,

equipment

parts,

bulk salt, sugar, or fertiliser etc., confectionery, spices ...

anything that is bagged is a target for AUTOpack™.

AUTOpack™

can extend the reach of automated packaging because it inherently

supports a simple and potentially small and inexpensive system

that would be tolerant of workflow variations and interruptions.

AUTOpack™

is a new approach in machine-handleable bags, for fully automated

bulk packaging and for smaller applications like agricultural/produce

packaging (carrots, potatoes, radishes, apples...) and a range

of industrial and commercial packaging (and potentially in-store

checkout bagging).

AUTOpack™ will

compete with the two main automated bagging technologies:

form-fill-seal bags, with 'preopened' asymmetrical bags.

(Don't forget that much bagging is still done with the ordinary

tedious purely hand-operated

bag.) Because of AUTOpack's™ flexibility, economy,

and the simplicity of the machinery that will handle it,

it has the potential to change the way certain types of industrial

and agricultural packaging is done. For example, this technology

is inherently less expensive and more portable than existing

bagging technologies, so one can imagine individual farms

or groups

of them owning

their own machinery that is portable and goes right to the

field if necessary, or adapted onto harvesters, as well as

used in the barn. The

technology is also inherently tolerant of variations in processing

speed,

and outright stoppages, without waste. It is thus suitable

for "when ready" cycle completion.

Attention

engineering and machinery companies: we are seeking

partnerships for the bag-handling

machinery.

We

envisage

a substantial

market,

ranging from short-run agricultural packaging, through

light commercial (kits, confectionery, parts packaging),

potentially all the

way to enhanced checkout stations that present an opened

bag for ready for filling by checkout staff or customers.

There is scope for your engineering expertise to result

in patents that build your company, consolidate your strategic

position, and expand your markets. Please contact us for

discussions.

|

A

bag that can be opened reliably by a machine

~ for filling stations that are semi/completely mechanised ~

Until

now --- the problem with getting a machine to open a bag

is that

the machine would have to work like people do, and sense

that it had gripped one layer (not two). That would require

more perception

and precision than is practically available in machines. SNAP™ solves

this problem by drastically reducing the requirement

for perception and precision. The cutouts in alternate pleats

of the bag make it possible for a low-precision machine to

grasp each of the four 'corners' of a bag, open it, and hold

the bag open. |

Suitable

for an automated bagging station, AUTOpack™ is

a bag that can be handled and fully opened by a machine. The bags

would be on a roll fed from the bottom (from top is possible but

requires an extra step in handling). The bags shown are 'flat-top',

but they could have handles (like T-shirt bags, or as punch-outs).

If bottom-feed,

the bag could be filled before or after detaching from succeeding

bag; filled bags would be then either left attached (giving strips

of filled bags, workable if contents are light and not too bulky)

or could of course be detached.

If top-feed, the bag has to be fully separated from the succeeding

bag before filling.

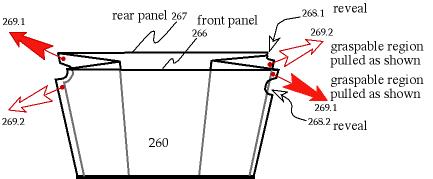

Each bag has

four easily-accessible grasping points so that they can be fully

and positively opened by machines. Each grasping point is immediately

accessible without the need for rubber fingers etc. to separate

layers.

How would the

bagging machinery work?

The handling

machine grips are to be aligned with the bag's grasping points.

Even if the film is very clingy the bag will still be openable

because the grip and action are so positive. The anticipated application

would see these handled on rolls for feed into filling machines.

Bag feed could be upward or downward. The fingers grasping the

pair of tabs corresponding to the back of the bag would often be

rigged to remain stationary, while the 'front' fingers would move

in unison, pulling the front away (or first to one side to break

the interlayer cling, and then away to fully open the bag mouth,

a kind of zigzag motion). Many forms of actuation

are possible, many kinds of fingers, etc., so, as said above, there's

plenty of scope for innovation beyond the basic principles laid

out here.

Bagging machines

could range from semi-automatic to fully automatic.

Semi-automatic:

manually activated once per bag. E.g., as the operator has completed

filling one bag, s/he can trigger a switch) to close and detach

the filled bag while a new bag is advanced, opened, and presented

for filling. Operator can pause any time without causing a foulup

and waste of empty but sealed bags, etc. That is not the case with

form-fill-sea bagging. That means AUTOpack is much more

suited to small-scale and short-run packaging than competing form-fill-seal

bags.

Fully automatic:

the filling operation can be automated and can trigger presentation

of a bag and removal and sealing once it is filled. If there is

a power failure, there is no need for a warm-up time before restarting

as with form-fill-seal baggers, and no waste of material or need

to clear out melted film or malformed bags caused by the interruption.

With Autopack, the bags are already made.

AUTOpack means

that a regular but intermittent user can afford a simple machine

and a supply of custom-printed bags that previously would have

been impractical for small users.

Applications:

... automated

bagging for short-run tasks that require flexibility. E.g. 40 tons

of carrots/onions/marbles/washers etc. in bags (4 oz to 40 gallon,

etc.), bags to be machine-opened, filled, machine-closed (weld,

tie, staple, tape, etc.), & the next bag to be advanced and

opened, etc.

back

to top

|