Applications? ... for BIG bags: refuse/trash bags, utility, leaf, garden etc; ... and for SMALL bags: produce, parts, deli, and medi-covers™ (for medical equipment where sterilisation isn't possible)

Finishings? ... as any flat bag: straight-top or wave-top, handle holes, doorknob holes, etc.

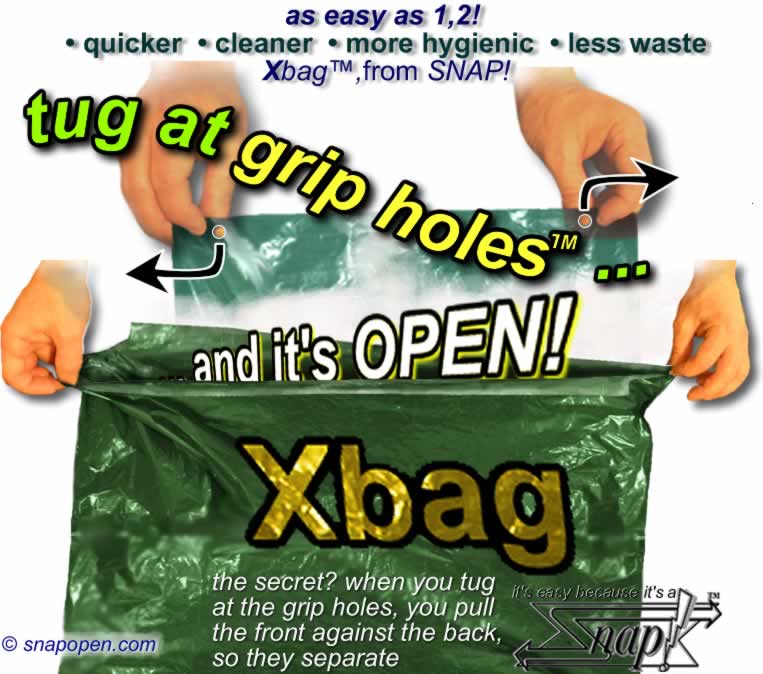

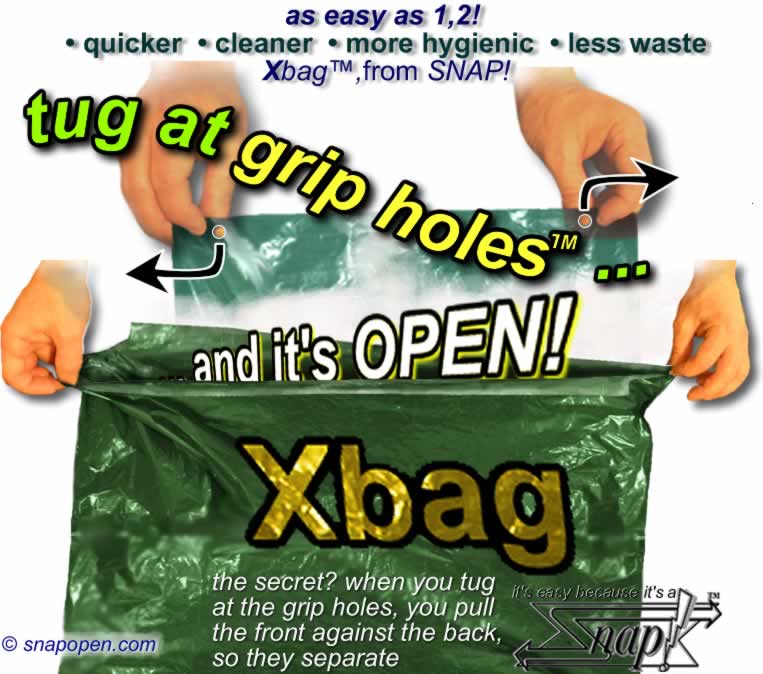

Presentations? ... singles (usual for large bags), stacks, boxed, wickets, etc., or rolls -- side-by-side -- for convenience, esp. with smaller bags.How do they work? (SNAP's proprietary technology) a light tug at Xbag's grip holes™ pulls front & back in opposite directions so the 'cling' lets go

grip holes™ show where grasping points™ are

Technical: Xbags are a subtle change from the conventional flat bags. Conversion is easy (just add punches). What materials? ... just as you use now, or simpler.

Licensing info: SNAP Film Tech, www.snapopen.com